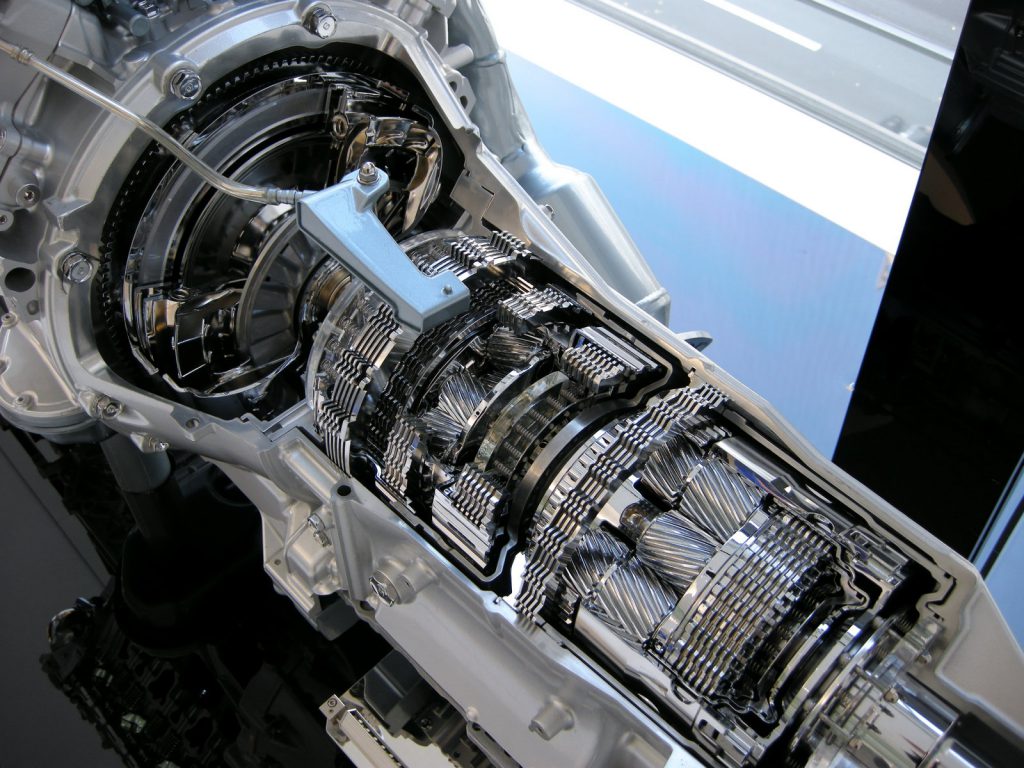

Before describing the methods of repairing gearboxes, let’s talk about what breakdowns (and the causes of their occurrence) occur in this node.

By switching the selector switch to the neutral position, the motorist catches extraneous noises coming from the checkpoint:

- the bearings on the drive shaft are worn out;

- the bushings intended for the installation of needle bearings were completely worn out;

- it is necessary to find the driving gears for the third and fourth gears and the driven gears for the first and second gears (the inner diameter has worn out in them);

- the working surfaces on the gear teeth have crumbled or worn out;

- there is a spline shaft (designed for reversing the car), in which the axle bushings were worn out.

The operation of the checkpoint is accompanied by strong knocks (when operating with a load) and weak knocks (when operating without a load):

- it is necessary to check all gears in the gearbox for the integrity of all teeth.

Due to the complete lack of synchronization, an attempt to change gear at the checkpoint is accompanied by strong knocks:

- it is necessary to inspect the locking ring of the synchronizer, on the conical surface of which the thread may be worn out;

- it is necessary to inspect the synchronizer crown on each of the gears (the conical surface may be worn there).

Any of the four gears switches off spontaneously:

- it is necessary to periodically inspect the synchronizer and the driven gear of the reverse gear switch (in these parts, the ends of the teeth on the crown may be worn out);

- the driven gear of the reverse gearshift and the clutch form an excessively large gap at the interface;

- the gears are not fully engaged due to the fact that the gears do not engage to the full depth of the teeth on the crown when shifting gears;

- needle bearings and gears form large gaps at the landing site;

- it is necessary to inspect the locking device of the gear switch, the springs of which work with insufficient force;

- the fork is worn out in the gear mechanism.

The reverse gear turns off spontaneously:

- it is necessary to check all connected gears, the ends and surfaces of the teeth of which may wear out;

- the transmission is not fully switched on, because when it is switched, the teeth of the connected gears do not engage the entire width of the tooth;

- it is necessary to inspect the locking mechanism of the gear switch, in which the springs may work with insufficient force;

- the driven gear for the reverse gear switch and the hub at the interface form a gap with a width greater than the permissible one;

- the reverse gearshift mechanism works with a worn fork;

- the spline shaft and the intermediate gear of the reverse gear switch at the interface form a gap with a size larger than the permissible one;

- it is necessary to inspect the spline shaft of the reverse gearshift mechanism, the sleeve of which may wear out, or the fit may weaken at the junction of these parts.

All transmissions are turned on with great difficulty:

- it is necessary to inspect the clutch in the synchronizer or the driven gear of the reverse gear mechanism. A rivet may form on the inner surfaces of these parts;

- also, in the gear synchronizer, it is necessary to check the slots on the crown, which can also be riveted and nipped;

- it is necessary to check whether the bolts securing the forks to the rods and holding the slider are sufficiently tightened;

- the rod is jammed together with the slider.

The inability to turn on any of the gears:

- when you turn on the transmission, you need to inspect its entire mechanism, in which the fork legs may wear out or break;

- the driven gear of the reverse gear switch (or clutch) jams;

- the gear synchronizer for this transmission is defective (the crown is broken).

It is impossible to turn on the reverse gear:

- the drive gear of the reverse gear switch jams at the junction with the spline surface of the shaft;

- it is necessary to check whether the bolts securing the forks to the rods and holding the slider are sufficiently tightened;

- the gearshift lever is deformed or worn out.

When trying to switch, two gears are switched on simultaneously:

- the stock locks (or their pushers) were worn out.

Difficulty switching any of the gears:

- the nut on the bolt securing the clutch and slider is poorly tightened;

- the locking bolt from the slider is poorly tightened;

- the lock nut on the clutch is loosely tightened.

It is not possible to turn on 3 and 1 gears:

- displacement of the gearshift housing.

Turning on the main gear is accompanied by a strong noise:

- in the main gear, the bearing on which the drive gear is mounted is in a destroyed state;

- the differential is functioning with broken bearings;

- the main gear operates with an increased clearance.

The differential is constantly knocking:

- the teeth in the gears were worn out;

- the bearing surface for the satellite gears was worn out;

- the support surface for the cracker of the semi-axes of the shaped groove of the semi-axial gear was worn out;

- weak attachment of the driven gear to the body surface in the differential;

- the satellite fingers are worn out.

All the above faults can be eliminated only by installing new parts instead of the failed ones.

Find the necessary spare parts here

Avaruosad.ee – online auto parts store

Need spare parts for your car? Call for free consultation:

- +372 56 812 812

- info@avaruosad.ee